JBS (It’s Just a Box Syndrome) and Its Cure

How the Packaging Triangle Model Can Transform Communication About Package Development

Houston, we have a problem…

The life sciences packaging profession has a communication problem. Those of us who consider ourselves “insiders” know that the nature of healthcare packaging development is extremely complex, requiring high levels of expertise and technical rigor. Yet our non-packaging colleagues or business partners may suffer from It’s Just a Box Syndrome (JBS).

When JBS creeps into project decision making, there’s a higher risk that critical packaging requirements may be overlooked, resulting in planning oversights, delays, or cost overruns. Everyone loses when this happens!

How, then, can we as life sciences packaging professionals counteract JBS? How can we communicate the complexity of our work without losing our audience in the details? To do that, we need a model.

Models make it possible to describe something large or complex in simple terms, showing the interrelationship of elements or ideas. An exceptional model is also visual, scalable, and adaptable to different scenarios. It can be used for an overview of the topic or a detailed discussion to demonstrate mastery of the complexity involved.

Wouldn’t it be great if there were such a model for packaging? Thankfully, there is! It’s called the Packaging Triangle… the perfect cure for JBS.

What is the Packaging Triangle?

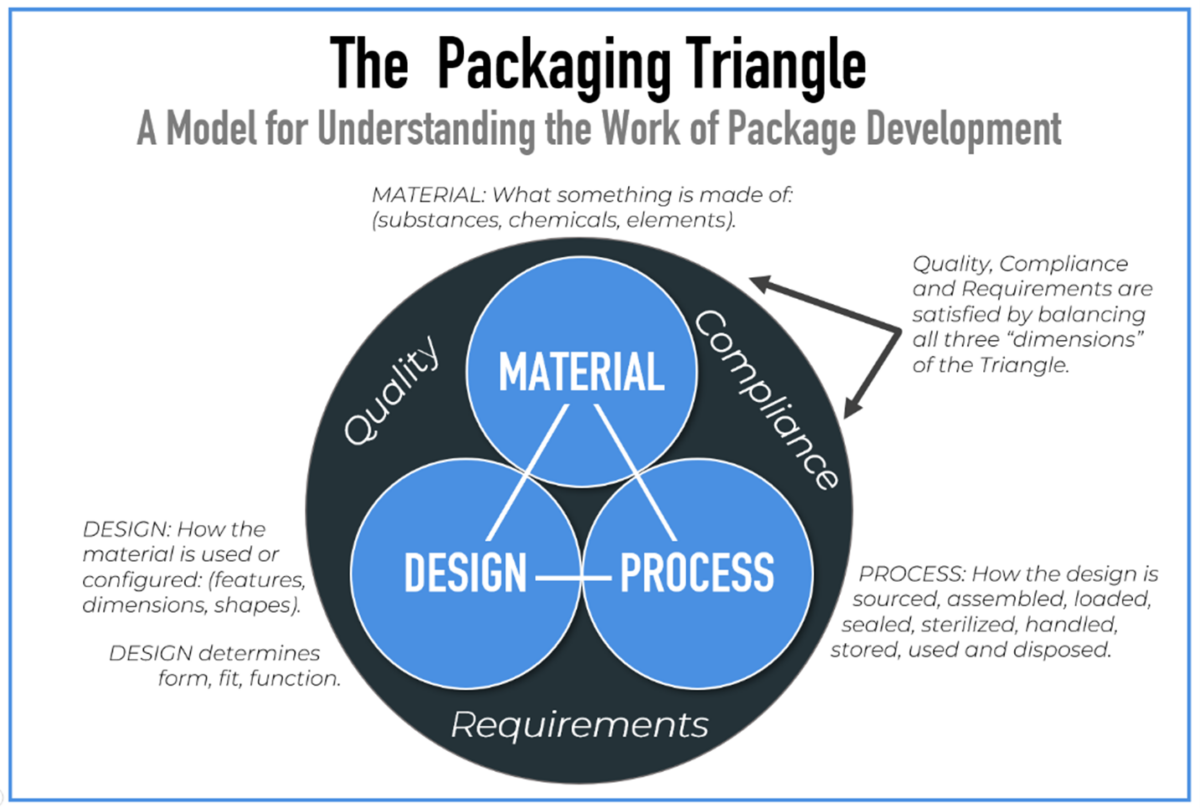

Figure 1: The Packaging Triangle Model

The Packaging Triangle is a model that describes the work of package development along three dimensions: material, design, and process (see Figure 1).

The three dimensions shown in the Packaging Triangle are interdependent. It’s very difficult to choose a material without considering how it will be used in a design or what process will be required to mass produce it. Any change to one dimension of the triangle will invariably affect the other two. This interrelationship is especially important when discussing design changes.

The Triangle also exists in a larger context, which consists of requirements, quality and compliance. Figure 1 shows the requirements at the bottom of the diagram to illustrate their foundational nature. When the right requirements are captured, well-defined, and satisfied by the material/design/process of the packaging application, quality and compliance will likewise be fulfilled.

Curing JBS in Three Powerful doses Using the Packaging Triangle

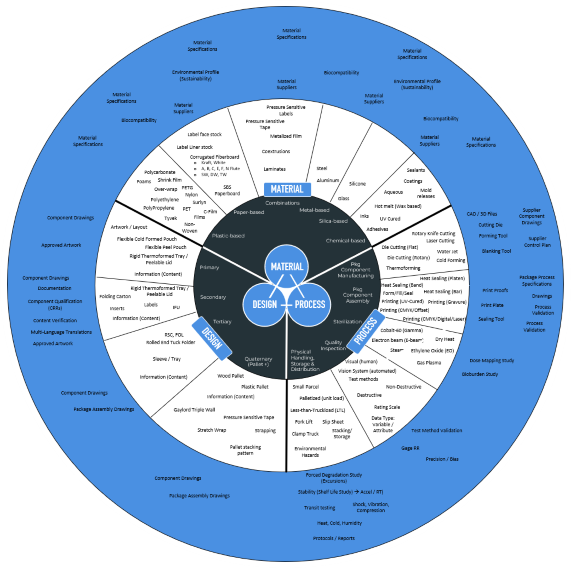

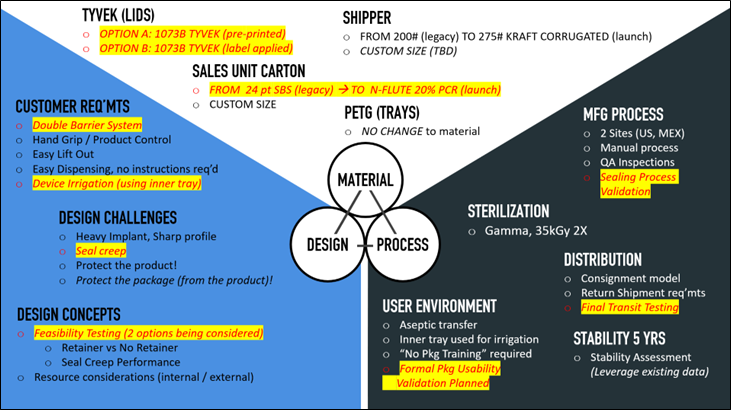

Figure 2: The Packaging Triangle Detailed View

1. Communicating the Detail (on purpose):

Sometimes, when it’s obvious that business partners have a bad case of JBS, it may be necessary to purposely impress upon them the complexity of our work to earn some respect and perhaps even save the project from critical oversights waiting to happen. This can be quickly accomplished in a single potent dose using the detailed view of the Packaging Triangle (Figure 2).

This depiction of the work makes no apology for complexity. The expressed purpose of showing this view is to directly counter JBS! Figure 2 shows three concentric circles. The inner circle lists various categories of material, design, and process whereas the middle circle lists specific examples within those same categories. The outer circle shows various types of activities (such as testing) including required documentation and objective evidence.

Clearly, this work is much more than “Just a Box”!

2. Communicating Critical Tasks or Focus Areas:

Once the worst symptoms of JBS have been cleared with the detailed view (Figure 2), it’s time to put our business partners at ease because despite the complexity of package development, we have things under control and have identified the key focus areas.

The focused view (Figure 3) can be used in a number of ways. It can be used as a simple project update, limited to critical items. It could also be used to highlight to the Team our awareness of key customer requirements, packaging topics for discussion, or decisions with impact to project timing. This view is another credibility builder, but is kinder to the audience than Figure 2.

Figure 3: The Packaging Triangle – Focused View

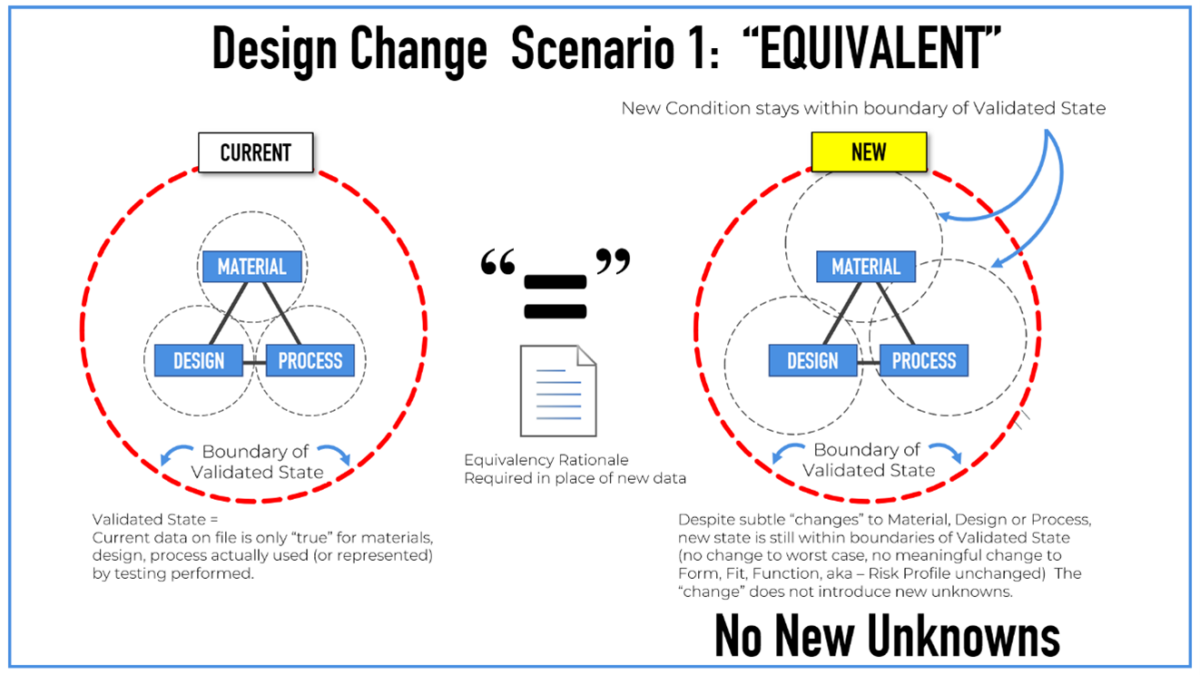

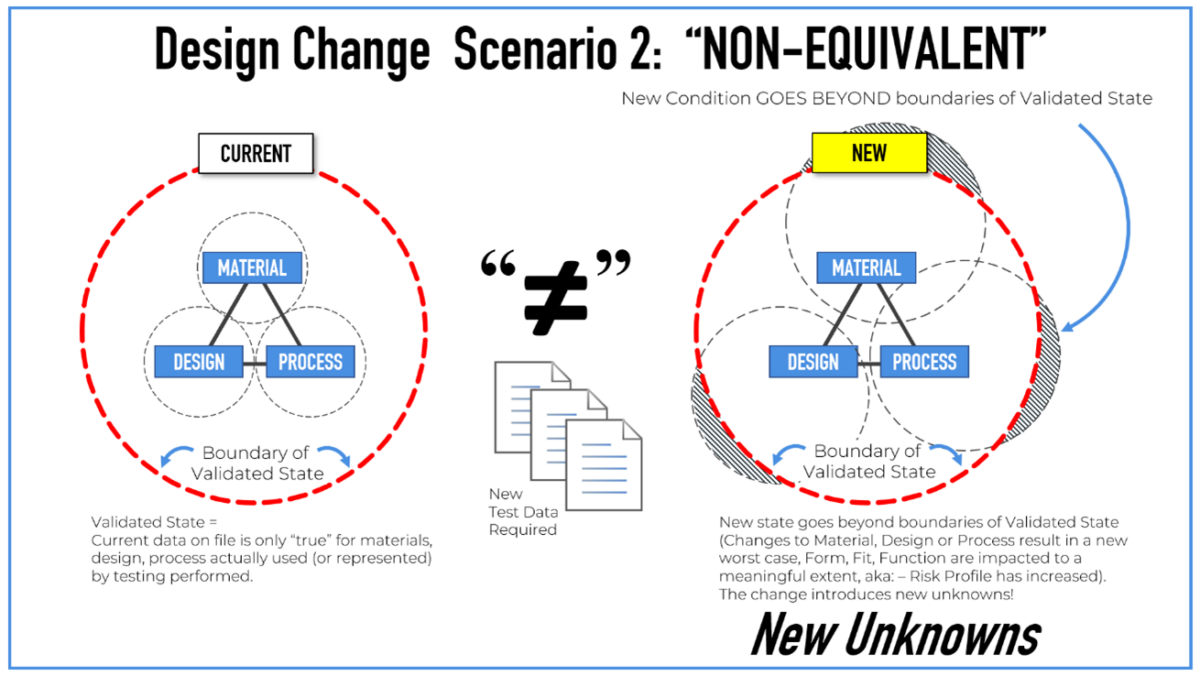

3. Navigating Design Change Discussions:

The third dose using the Packaging Triangle concerns facilitation of design change discussions. With supply chain disruption plaguing the entire life sciences industry, material swap-outs are a popular solution. Rather than just talking about such situations, Figures 4 and 5 illustrate two design change scenarios using the Triangle. These diagrams make the decision visible, thereby delivering real value to design change conversations with business partners.

In Figures 4 and 5, the Packaging Triangle is placed within a circle (the red dashed outline) which represents the boundary of the current validated state (the limits of current test data supporting the materials, design, and process used for the currently marketed product). Figure 4 represents a case where subtle changes in material, design, or process have stayed within the boundaries of current test data on file (where an equivalency rationale is possible).

Figure 5 shows a non-equivalent change, where the new condition of material, design, or process exceeds the boundaries of the current data (new testing is required).

Figure 4: “Equivalent” Change (Rationale possible)

Figure 5: “Non-Equivalent” Change (Testing Required)

Houston, problem solved . . .

Yes, JBS can be a real problem, but it can be cured using the Packaging Triangle model. This article has shown an overview of the model and demonstrated three ways the Triangle functions as a powerful tool for communication and building credibility with our non-packaging business partners.

It can be used to make a frontal assault on JBS, if necessary, to demonstrate the complexity of package development. It can be used in a more audience-friendly manner to provide packaging updates or highlight key topics or decisions. Lastly, it was demonstrated how the Triangle can bring real value to design change discussions.

But you already knew packaging wasn’t “just a box.” With a few doses of the Packaging Triangle, now your business partners will too!

Written by Brian Farison, Technical Fellow at Network Partners.