5 Key Reasons to Get a Global Labeling System

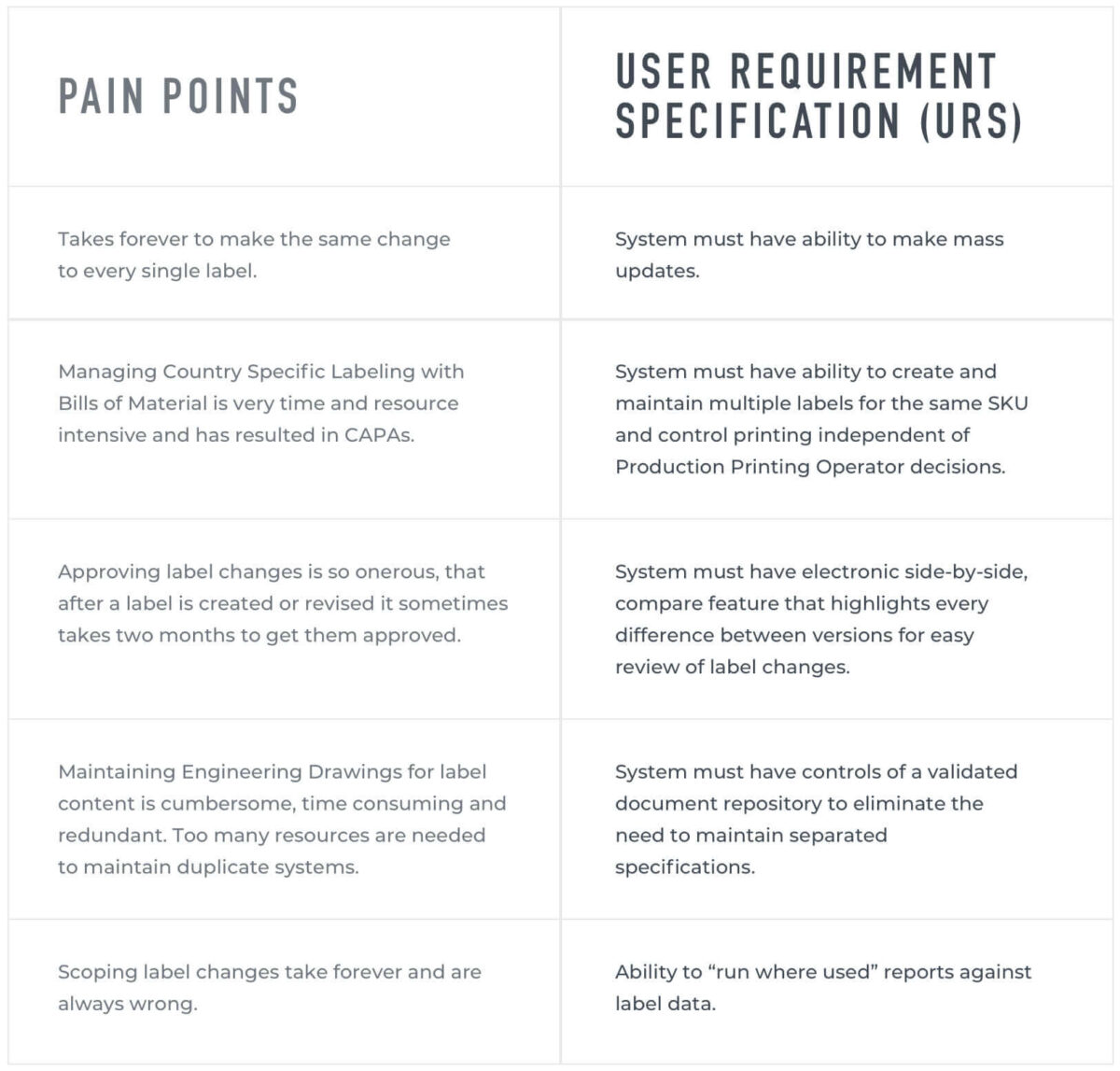

When you conduct a Labeling Process Assessment and collect the pain points from the stakeholders, a lot of these pain points will be mitigated by identifying label elements, defining roles and responsibilities, and simplifying your procedures.

The remaining pain points are the areas that the Global Labeling System (GLS) will address:

REASON 1

MASS UPDATES

Change to a manufacturer’s address, change of your Notified Body, change of your European Authorized Representative, addition of symbol for a Medical Device, adding a URL under your “see instructions for use” symbol?

You may not have a one-to-one ratio for your label files to each product label, but what if you could update every CE mark on 5,000 labels with less than a dozen keystrokes?

Get a pre-approval memorandum of understanding from your label approvers for updating the EAR, then change and approve 10,000 labels with a new CE notified body number on a Monday. Add a Medical Device symbol to each of your 30 label formats in less than a week. Not only would this save both time and money, but you’re also not paying the opportunity costs by tying up your labeling resources on a year-long project.

REASON 2

COUNTRY SPECIFIC LABELS

You create and identify the primary label, the label that goes on your folding carton when you pack it out, by coding it in the system as a primary label, and you configure all the printers on your packaging lines to be configured to print primary labels.

You can create and identify another label from the data associated with the same item number, and code it as, let’s say a Country Specific Label. You have another workstation(s) in your Distribution Center that you configure to print Country Specific Labels, then you configure the system to require a “country” be called out before it prints a Country Specific Label. All these configurations are in the system and invisible to the operators.

Now you do not have to have a particular label ID on your Bill of Material to call out the Country Specific Label for China. You just scan the product to get the item number, you scan the pick list to identify the product is destined for China and the label printer prints out the China Specific label. You can make the system confirm the label by scanning the bar code on the Country Specific Label before it can print another label; built in line clearance. (You can even make it simpler, but step by step makes it easier to explain).

REASON 3

COMPARING VERSIONS

Approving labels is a nightmare. I, as the Associate Director of Labeling at one point, dreaded the change request with 50 label revisions –

• I could only do ten at a time.

• Interruptions meant starting over.

• Eye strain or headache was expected.

• Comparing redlines to revisions, comparing descriptions to revisions is tedious and finding unintended changes is just a crapshoot.

Imagine simply having the current and revised label presented side by side on your monitor with every change between the two versions highlighted electronically. Every change, intended or unintended is highlighted. You can approve labels and drink coffee at the same time as you scroll from label to label making sure the differences are the intended changes. This is my favorite feature in the current Global Labeling Systems.

REASON 4

ELIMINATING ENGINEERING DRAWINGS FOR LABEL CONTENT

The current Global Labeling Systems have work-flow built into them and are Part 11 compliant; they have version control and they have audit logs, so your labeling system serves as a validated document repository.

For companies that use engineering drawings to control label content, you can leverage your GLS to eliminate these drawings. You’ll still need label stock specifications, but for the purpose of specifying what the label looks like, the latest approved version of any label is your label specification. Get rid of redundant information and stop reviewing and maintaining these, that’s a time saver.

REASON 5

SEE YOUR LABELS

Why are label changes so hard to scope?

Because when you cannot see the labels based on their content, you’re stuck trying keep track of ever-changing label I.D. numbers. It is shameful that the group responsible for identifying the company’s product cannot identify the labels associated with those products.

With a GLS, you’re able to sort and search your label content any way you wish. Changing your European Authorized Representative, query your database for all labels that have a CE mark, changing to a raw material that is made phthalate free, search for labels that have the phthalate warning. With the ability to run custom reports, you’re not restricted to label content, you can ping your audit log for when you printed labels. Know when a questionable lot of raw material was put into production, you can see all the lots of those products that used that material. Easier to confirm specific lots with DHRs than going through all the DHRs to scope the issue. Being able to query the Audit Log, immediately became the go to method for Quality Assurance to scope all production issues.